1850

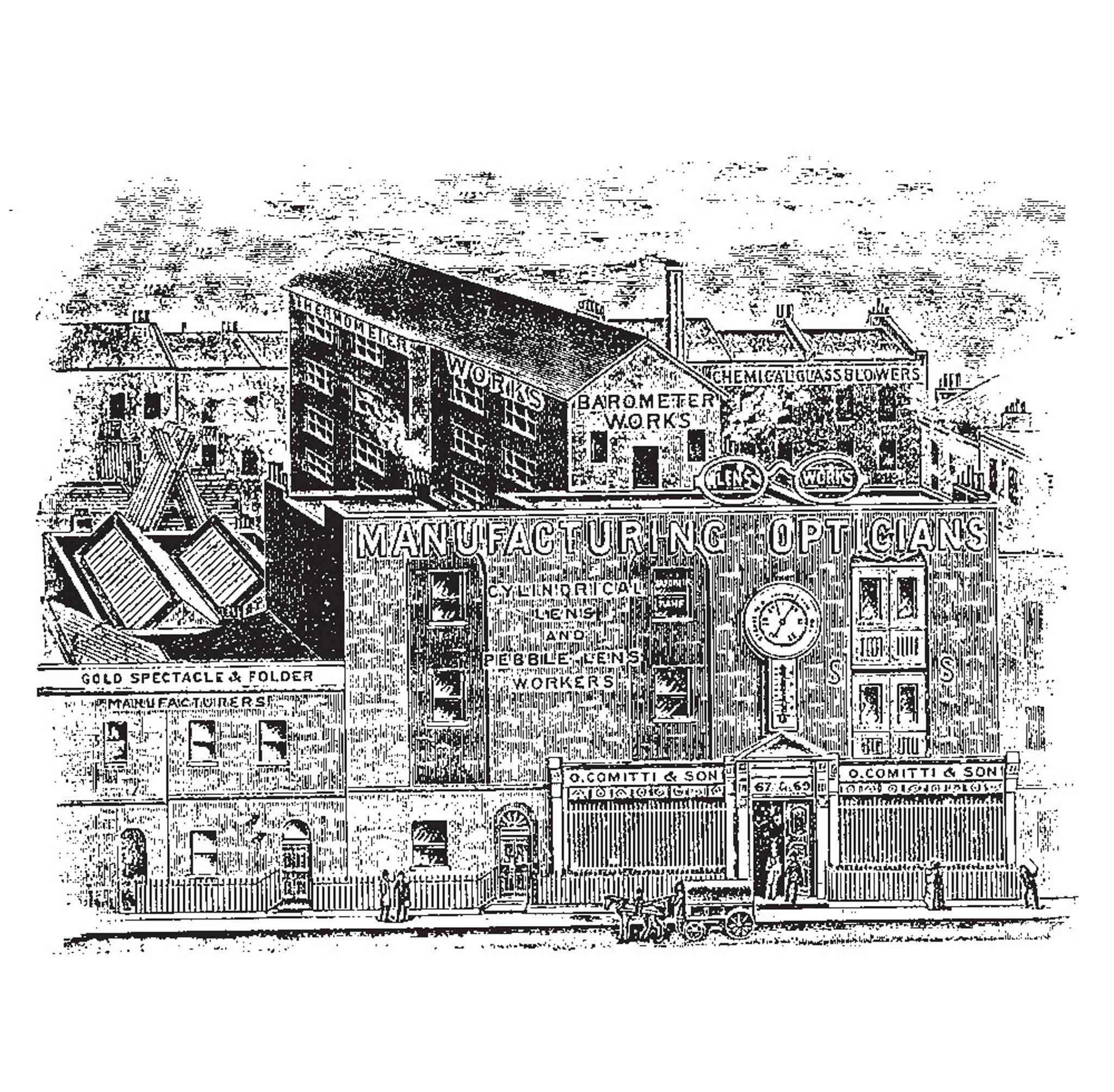

Onarato Comitti travelled to London from the Lake Como area of northern Italy. He was a skilled instrument maker with a heritage that can be traced back to Evangelista Torricelli, a student of Galileo, who made the first mercurial barometer in 1643. He sought his fortune in the most advanced industrial nation in the world and established his workshops in Clerkenwell, the centre for instrument and clock making in London.

1888

Onarato Comitti received the Diploma D'Onore for the quality of his workmanship from the Exposizione Italianna Londra. Onarato's son Luigi became chairman and Comitti was registered as a Limited Company at Companies House in 1897.

1899

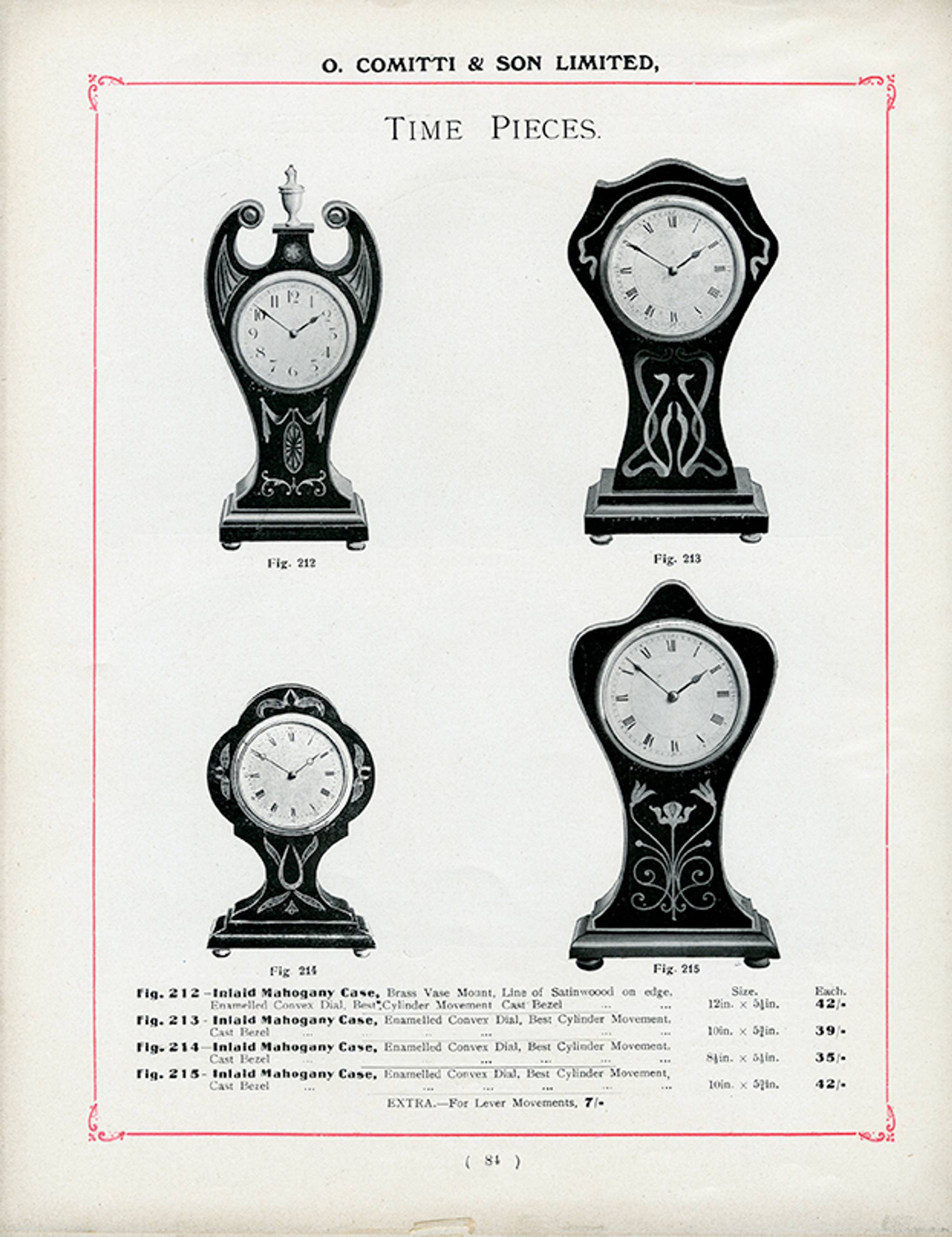

Comitti published a broadsheet showing registered patents and a comprehensive collection of mercury and aneroid weather instruments. Barometers for marine use, Admirals Fitzroy's instruments designed for recording data across the Britain for coastal and national forecasting, Fortin barometers for scientific research, Pocket Aneroid for altitude measurement, the companies Improved Torricelli Barometer, sophisticated Royal Polytechnic Barometers recording Barographs and mantel barometers including timepiece movements.

1903

The Barker family takes control of the company after George Barker married Luigi Comitti's daughter and becomes a Director in 1903. He is appointed chairman and steers the company through the difficulties of WW1 and introduces a new collection of clocks.

1946

George's son, Ronald James Barker, becomes a Director of the company following his service as a tank commander in WW2 in the North African Campaign.

1981

In 1981 Comitti was commissioned to make a royal wedding barometer to mark the occasion of the marriage of the Prince of Wales to Lady Diana Spencer and Ronald Barker retires. In 1983 his sons take control of the company and in response to growing demand re-locate the business to Walthamstow in East London

1990

Comitti is recognised as the UK's leading maker of classic English clocks and barometers. The new collections included longcase, wall and table clocks as well as specialist commemorative timepieces. The company is presented with the UK Jewellery Awards as a Luxury Objects finalist for our inlayed floor clock, a piece that reflects the superb workmanship of 17th century makers.

2002

Comitti offer for the first time its flagship model, a unique version of John Harrison’s Sea clock, the Navigator. In response to growing competition for overseas the company changes its business model, focusing on aspirational quality and bespoke finishes and in 2007 re-locates its workshops to Ongar, Essex to facilitate that new direction.

2012

A special version of the Royal Greenwich Regulator is presented to Her Majesty Queen Elizabeth 11 on the occasion of Her Diamond Jubilee and is now part of the world famous clock collection at Buckingham Palace.

2013

Comitti launches the Meridian Co-Axial Table Clock. A world first and unique contribution to the story of the British Clockmaker at Baselworld in Switzerland

170 years of english barometer and clockmaking

The arts of

comitti

There are various different processes that come together to make each unique piece. Click on each process below to see more detail around the arts of Comitti.

meet the makers

The enduring appeal of traditional English clocks and barometers can be attributed to the diversity of the finest craft skills required to make them. A visit to Comitti’s workshops reveals a team of dedicated artisans working with equal amounts of skill and inspiration.

Chris Atkinson

Clockmaker & Restorer

Chris trained as a clock and watch maker and began work with Omega Watches in Hatton Garden in 1975. He discovered he had a passion for antique clocks and became particularly interested in fine clock movements. In 1990 he became a member of the British Horological Institute.

He has acquired over 40 years of instrument making, engineering and clockmaking experience and became part of the Comitti team in 2005. He is responsible for building the Navigator and the other specialist movements. He also works in the service and restoration department.

He recently played a significant part in the film about the making of the Navigator timepiece featured in the Made in Britain program for television.

Chris Atkinson , Clockmaker & Restorer

Edmund Barker

Cabinet maker & machinist

Edmund studied Fine Art at the University of the West of England. After graduation he determined that his passion was furniture design and construction and he enrolled at the Building Crafts College to build his technical skills. He was then invited to serve an apprenticeship at the famous Edward Barnsley Workshop in Hampshire.

Having completed his training, he joined Comitti in 2015 to head up the wood workshop and is responsible for cabinet design and development, the machine shop, finishing and polishing. He is passionate about bringing contemporary ideas and design to take the company forward.

Edmund Barker, Cabinet maker & machinist

Anwar Caunhye

Cabinetmaker & finisher

Anwar began his career in woodworking at the age of 14 when joined a 5-year apprenticeship scheme cabinetmaking in Mauritius. He then built his own company at the age of 20, making a respectable name for himself and building a clientele for his renowned bespoke furniture. He has had a passion for working with wood his whole life.

He started working with Comitti in 1999 and has dedicated 22 years to the company. During this time, he has had the opportunity to develop his skills that now include marquetry, carving and polishing. He takes pride in his craftsmanship and is meticulous in his attention to detail. He recognises that people will always value fine workmanship and that a clock made by company will be valued by future generations.

Anwar Caunhye, Cabinetmaker & finisher

Bella Chipperfield

Chinoiserie Artist

Bella realised she has a passion for art at an early age and after school she did an Art Foundation Degree at Cambridge Regional College. After completing Music Hons degree at Royal Holloway University of London she become an art therapist, combining teaching, and working as a freelance artist.

Bella has been working as a professional artist for over 10 years specialising in portraiture, and illustration. In 2018 she became interested in Chinoiserie and completed a course in this unique artform under the supervision Alex Schouvaloff, an authority on Japanning and Gilding who graduated from the London Guildhall University, as a foundation to working with Comitti.

Bella Chipperfield, Chinoiserie Artist

Philip Halsted

Clock designer & maker

From a very early age Philip was a budding engineer, building his first clock at the age of twelve. He spent many hours in the home workshop of his father, who was a professional engineer by day and a keen clock maker in his spare time. Supervised by his father, the finished clock was the first to carry the name of W Halsted & Son.

At sixteen he started an apprenticeship as a scientific instrument maker at London University. After qualifying he set up his clock making business and worked with several British clock retailers, designing both limited edition and bespoke timepieces. Philip began designing and making prototype clocks for Comitti in 2008. These include the Greenwich, the Meridian, and the York. Philip is also a member of the Worshipful Company of Clockmakers, a City of London Livery Company.

Philip Halsted, Clock designer & maker

Tim Pemble

Engineer & clockmaker

Tim had an interest in how things are made from a young age and after school he became an apprentice toolmaker and studied engineering part time for 6 years.

His work experience includes making machine tools for making plastic moulding and extrusions, electro-acoustic devices, military optics and clockmaking.

Tim is an Incorporated Engineer and a member of the Institute of Engineering and Technology. He joined Comitti in 1996 working on instrument assembly, clock making, inspection and testing.

Tim Pemble, Engineer & clockmaker

David Samuels

Machinist & Instrument Assembly

David left school at 16 and joined an apprenticeship scheme at a local firm in East London. He served 3 years developing his skills in carpentry and joinery and achieved his City and Guilds qualification.

He worked at a shopfitting company for a further 7 years and joined Comitti in 1993 as a cabinetmaker.

David’s enthusiasm, attention to detail and interest in the diverse skills employed at the company has meant he has been encouraged to progress and develop his expertise in wood machining, polishing and clock assembly.

David Samuels, Machinist & Instrument Assembly